Sand Blaster For Sale Fundamentals Explained

The Only Guide for Dustless Blasting Near Me

Table of ContentsEverything about Grit BlastingAbout Sandblasting Near MeSee This Report about Sandblasting Near MeThe 7-Minute Rule for Sandblaster For SaleSome Ideas on Shot Blasting Near Me You Should Know8 Easy Facts About Sandblaster For Sale Explained

Damp unpleasant blowing up [edit] Wet rough blasting usages water as the fluid relocating the abrasives. The advantages are that the water catches the dust created, and also oils the surface. The water supports the effect on the surface, reducing the elimination of audio product. One of the original pioneers of the wet abrasive procedure was Norman Ashworth who found the advantages of using a wet process as a strong alternative to dry blowing up.

Reduced impregnation of blowing up material right into the surface area, dust reduction and the removal of static cling can lead to a spick-and-span surface area - sand blasting sand. Damp blasting of moderate steel will result in immediate or 'flash' rust of the blown up steel substratum due to the visibility of water. The absence of surface area recontamination additionally allows the usage of solitary equipment for several blowing up operationse.

Sand Blaster Harbor Freight Things To Know Before You Get This

A version of wet blowing up is vapor blasting (or vapour blasting; U.K.). In this process pressurized air is added to the water in the nozzle generating a high rate mist, called "vapor". This process is even milder than wet blasting, allowing mating surfaces to be cleansed while keeping their capacity to mate.

Blending fragments with water substantially decreases dust. Grain blasting is the procedure of eliminating surface deposits by using great glass grains at a high pressure without damaging the surface area. It is made use of to clean calcium deposits from pool ceramic tiles or any kind of other surfaces, remove embedded fungi, and also lighten up cement color.

In removing paint for vehicle body work, bead blasting is chosen over sand blasting, as sand blowing up tends to create a higher surface account than grain blasting. Bead blasting is usually used in producing a consistent surface finish on machined components.

Things about Sandblaster For Sale

The first blast wheel was patented by Wheelabrator in 1932. Hydro blasting is not a kind of abrasive blowing up as no rough media is made use of. Hydro-blasting, generally recognized as water blasting, is frequently used since it usually needs only one driver.

This approach is optimal for cleansing internal and external surfaces due to the fact that the driver is usually able to send the stream of water into places that are difficult to get to utilizing various other techniques. Another benefit of hydro-blasting is the capability to regain as well as recycle the water, minimizing waste as well as mitigating environmental impact.

The most usual micro-abrasive blasting systems are industrial bench-mounted systems consisting of a power supply and mixer, exhaust hood, nozzle, as well as gas supply. Either the nozzle or part can be moved in automated procedure.

The Ultimate Guide To Shot Blasting Near Me

Automated blasting is regularly just an action in a larger automated procedure, generally entailing various other surface treatments such as prep work and also layer applications.

The air compressor offers a huge quantity of high stress air to a single or numerous "blast pots". Blast pots are pressurized, tank-like containers, full of rough material, utilized to enable an adjustable amount of blowing up grit into the primary blasting line. The variety of blast pots is determined by the volume of air the compressor can give.

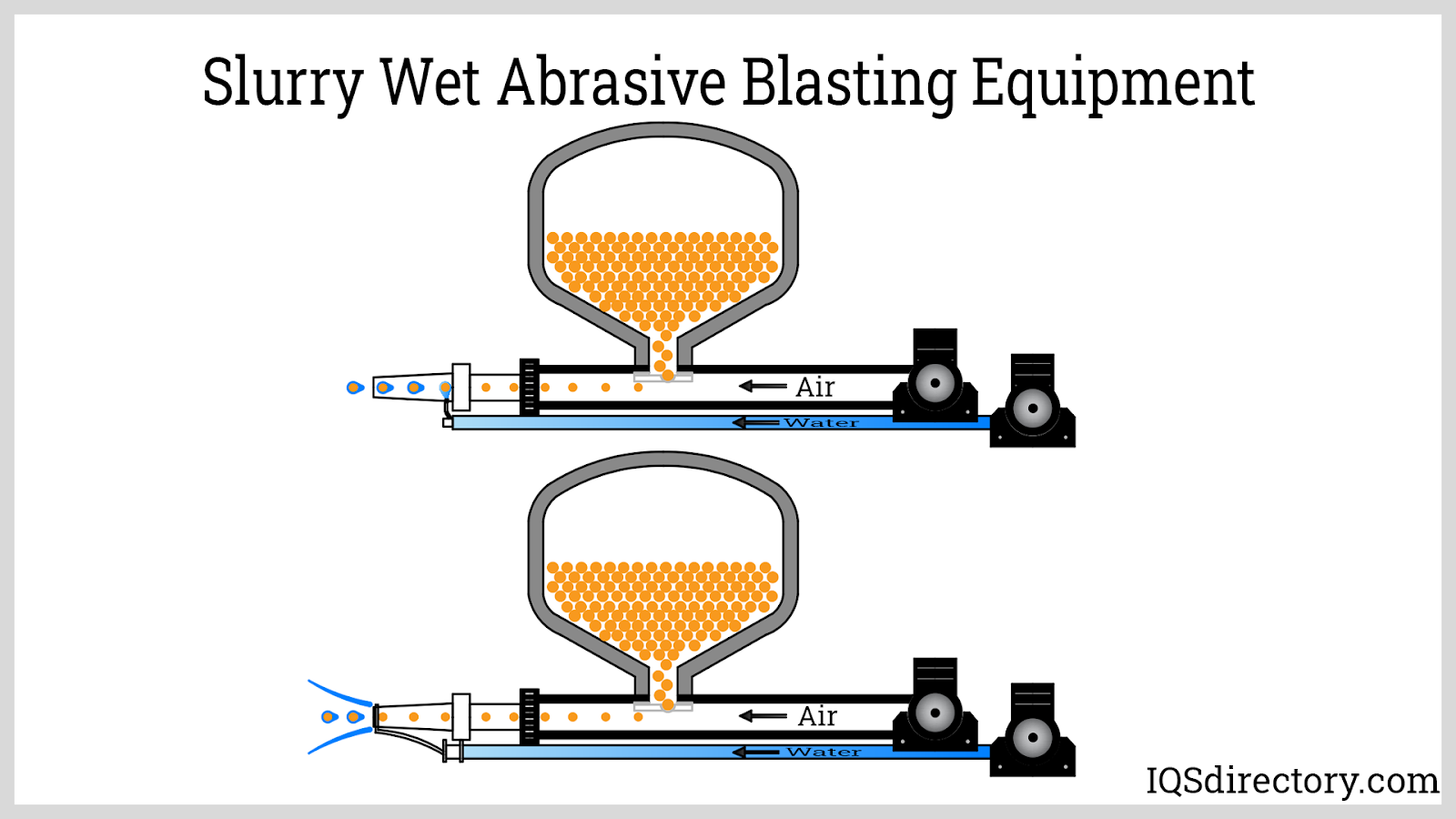

Others are hopper-fed kinds making description them light-weight as well as a lot more mobile. In wet blowing up, the abrasive is presented into a pressurized stream of water or other fluid, developing a slurry. Damp blasting is usually utilized in applications where the marginal dirt generation is desired. Portable applications might or may not reuse the rough.

The Ultimate Guide To Sandblasting

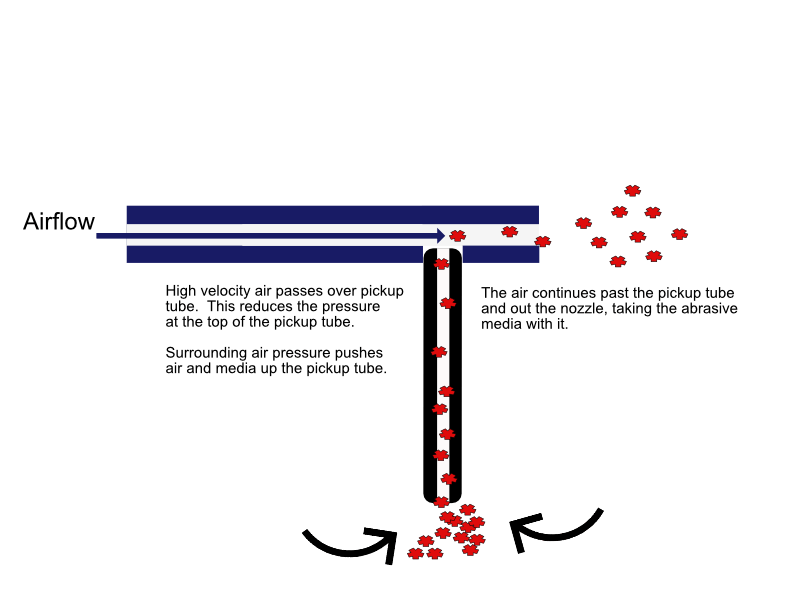

There are 3 systems normally utilized in a blast cupboard. Two, siphon and pressure, are dry as well as one is wet: A siphon blast system (suction blast system) uses the compressed air to create vacuum in a chamber (referred to as the blast weapon). The adverse pressure draws rough into the blast gun where the compressed air routes home made sand blaster the abrasive through a blast nozzle.

Nozzles come in a range of shapes, dimensions, and also products. Tungsten carbide is the liner product most usually used for mineral abrasives. Silicon carbide and also boron carbide nozzles are much more wear immune as well as are commonly used with more difficult abrasives such as aluminium oxide. Inexpensive unpleasant blowing up systems and smaller sized cabinets make use of ceramic nozzles.

Not known Factual Statements About Harbor Freight Sand Blaster

The vessel is pressurized to the very same pressure as the blast tube affixed to all-time low of the stress vessel. The abrasive is metered right into the blast tube and conveyed by the compressed gas with the blast nozzle. Wet blast closets utilize a system that infuses the abrasive/liquid slurry right into a compressed gas stream.